Step 1

Consulting & feasibility

We map your product, capacity and investment frame.

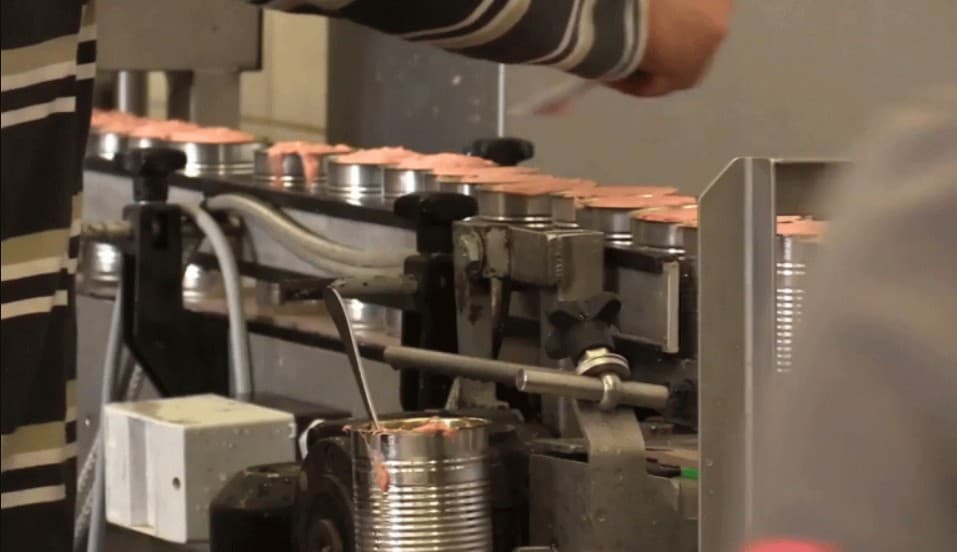

Canned Food Technology

Turn your fresh ingredients into ready-to-sell canned products with complete, engineered production lines for tomato paste, beans, tuna and more.

Shortcut to

your Industry

Zero-to-launch factory setup

See the complete journey from first consulting session to a fully running canned food factory – all in one clear roadmap.

Step 1

Consulting & feasibility

We map your product, capacity and investment frame.

Step 2

Line & machinery design

Complete layout and machinery engineering.

Step 3

Equipment manufacturing

Building and testing your custom machines.

Step 4

Civil works & utilities

Foundations, piping, cabling and services on site.

Step 5

Commissioning & training

Start-up, trial production and operator training.

Our reference plants

Simerco industrial group has participated in setting up more than 170 domestic plants and 35 foreign factories – here is a quick look at a few of them.

Each project is a complete journey – from feasibility and line design to commissioning and operator training – tailored to local standards and raw materials.

Canned beans & compote and jam production line

Canned tomato paste production line

Pharmaceutical production line

Canned tuna & pet food production line

Tomato paste & vegetable canning line

Multi-product canned vegetables line

Where should I start?

Choose your product, tell us your budget and we'll outline a realistic production line concept for your future factory.

Step 1

Choose your product line

Step 2

Set your investment level

Step 3

Get a line concept that fits

Once you pick a product line and investment level, we'll show you a realistic starting concept with capacity and configuration.

Production Lines

From raw material intake to ready-to-ship cans, each line is built from Simerco machines that are designed to work together.

Why Simerco

We don't just sell machines; we help you design a safe, efficient and maintainable factory that keeps running shift after shift.

Every machine is sized and configured to work with the next one, so you avoid bottlenecks and surprises.

Hygienic stainless-steel design, easy-to-clean surfaces and CIP-friendly layouts are standard.

Training, spare parts and technical support to keep your line running with minimal downtime.

Services

You can involve Simerco at any stage of your project, or let us handle the full journey from idea to production.

We help you design the full line layout, utilities and material flow based on your building and capacity.

All machines are manufactured, assembled and tested before shipment to your plant.

Our team supervises installation, runs test batches and trains your operators on site.

Remote support, spare parts and periodic maintenance plans keep your factory reliable.

Let's talk about your factory

Whether you're building a new plant or upgrading an existing one, we'll help you choose the right configuration of machines and utilities.

Prefer email? info@simerco.example